- Days

- Hours

- Minutes

Big bang or bricks?

Big bang, rip-and-replace change is often slow and risky with RoI hard to predict.

SCL-X helps supply chains accelerate innovation—taking iterative, agile steps that de-risk and deliver value today and build tomorrow’s advantage - brick by brick - through modular, composable design.

THE CHALLENGE

An Innovation Model Under Pressure

This turbulence creates an opportunity to rethink how innovation happens — moving beyond large, slow programmes and rigid, monolithic change toward approaches that are faster, modular, strategically aligned and capital-efficient.

When guided by a clear north star, pilots scale, benefits land sooner and leaders spend less time firefighting and more time driving continuous improvement.

"By the time we've got everyone's buy-in, the world has already moved on"

Supply Chain Director

Global Retailier

"Unless there's a burning platform, getting alignment is like pulling teeth"

VP Operations

Industrial Manufacturer

"Success depends on so many things outside my control but it's on me if it fails"

Senior Director, Supply Chain

Mid-Market Pharma

"We spend months of assessment on potential solutions but the size of the commitment means we kick the can down the road"

Transformation Lead

European Chemicals Manufacturer

"I've still got the scars from the last big project so I'm doubly cautious now. But I still need to show I'm bringing ideas to the table, especially with AI everything"

Supply Chain Director

FMCG

"The ERP upgrade is seen as a silver bullet but, in practice, we'll either bend our processes to fit or end up with layers of endless customisations"

Supply Chain Transformation Director

Consumer Goods

Unless you can prove payback in year one, forget about getting the budget approved"

Supply Chain Director

Food & Beverage

“The competitive advantage is already in our data. The problem is getting it out."

VP Supply Chain

UK Manufacturer

"Every time we want to change one process, IT tells us it will break ten others!"

VP Supply Chain

Global Manufacturer

"We've spent millions on visibility but we still don't have the data we actually need when disruption hits"

Logistics Director

Global Apparel Brand

THE VISION

From de-risking today's priorities to building tomorrow's advantage

Imagine if your teams could:

-

Spin up a new planning tool in weeks, not years

-

Test ESG dashboards without waiting for ERP approval

-

Deploy AI in pockets where it proves value, then scale fast

-

Combine best-of-breed partners with your own IP and data

You can't become composable overnight but you can start to think about which bricks you'll need and how you'll assemble them.

By applying iterative, agile principles, leaders can de-risk improvements to core systems, connect legacy platforms with new tools and lay the foundations for modular, composable architectures that harness the full benefits of your IP and advanced technologies like AI.

That’s how today’s safer bets turn into tomorrow’s competitive advantage.

"We didn’t need a global replatforming. We needed one capability to flex where the business needed it most. That’s where we started."

Supply Chain Director

Global Food & Beverage Group

“Instead of waiting 12 months to roll out a new planning tool, we plugged in a module that worked alongside our existing setup. It’s not perfect, but we’re learning and improving every month.”

Head of Planning Transformation

Consumer Goods Brand

“For the first time, we could say yes to a pilot without triggering a full IT project.”

Regional Logistics Manager

Retail

“It’s doesn't have to be about cutting-edge. It’s about moving faster with less risk and not breaking what already works.”

VP, Supply Chain Operations

Manufacturing

“Our advantage isn’t the tools, it’s how we’re assembling them to fit how we work. That’s not something you can buy off the shelf.”

Supply Chain Innovation Lead

Industrial Products

“We’ve stopped trying to convince everyone upfront. We run small tests, share the results and momentum builds from there.”

Transformation Lead

Distribution & Fulfilment

“We ran a pilot on inventory optimisation with a startup that had never worked in supply chain before. It cost us a few thousand pounds, delivered results almost immediately and it’s now embedded in day-to-day operations.”

Director of Supply Chain Excellence

Global Beverage Company

“The real unlock for us was standing up a lightweight orchestration layer that gave us a clean, real-time view of inventory. That became our own system of record and now both external tools and in-house microservices can read from and write to it.”

Head of Digital Supply Chain

Consumer Goods Manufacturer

“We standardised how we connect tools, not which tools we use. That gives us control without slowing innovation.”

Supply Chain IT Business Partner

Multinational Logistics Provider

“The biggest shift was moving from dashboards to agents. Instead of more reports, we now have microservices triggering actions - like replenishment or risk alerts - in real time.”

VP, Logistics

Global FMCG Brand

"Before, onboarding a new vendor took 6-12 months and three layers of approval. Now we can trial a module in a few days and only scale if it works.”

Head of Supply Chain Partnerships

Global Retailer

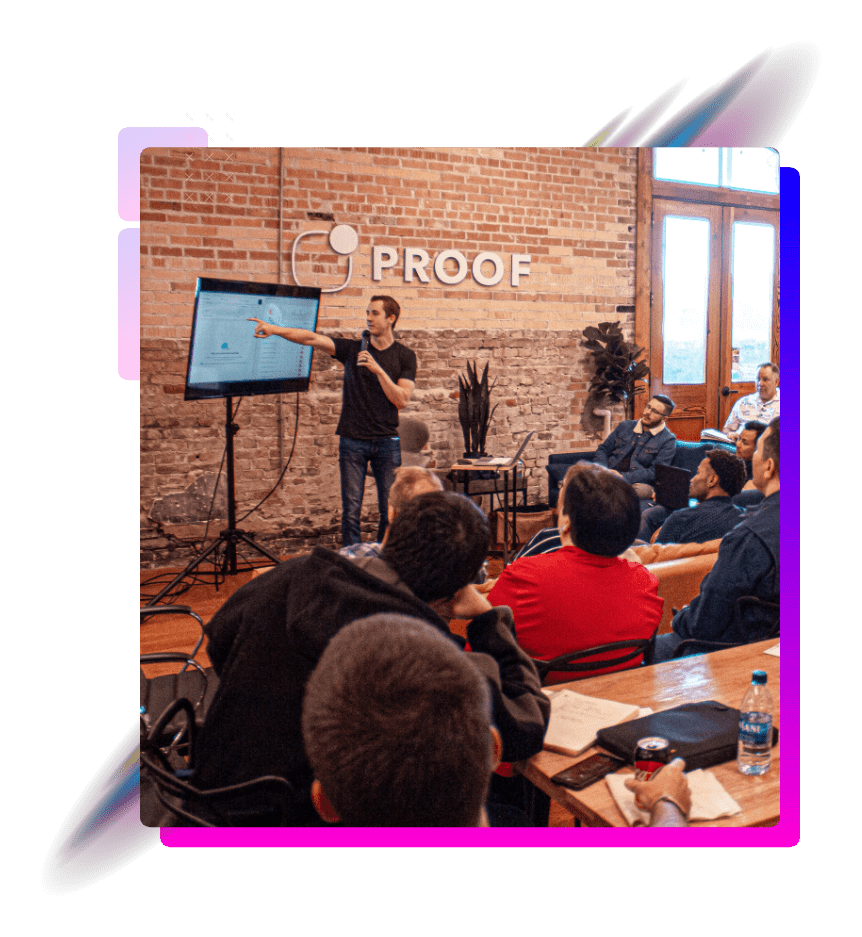

THE LEADERS

It's happening now...

True resilience isn’t just about visibility or supplier diversification, it’s about the ability to adapt quickly without destabilising what already works.

Life sciences, finance and media are already using modular and iterative approaches to test, scale and improve without full re-platforming. Supply chain leaders like Amazon, Ocado, Maersk and Zalando have been able to:

- Reduce time-to-value from months to weeks

- Scale proven pilots across regions without disruption

- Cut cost and risk from full-system overhauls

And it’s not just global giants. A UK-based food manufacturer cut pilot approval time by 40% using a modular approach. A European retailer used composable planning tools to improve forecast accuracy without waiting for an ERP upgrade.

THE SOLUTION

FROM IDEAS TO ACTION

The shift toward modular, composable innovation is already under way but every organisation’s path will look different. SCL-X exists to help supply chain leaders decide what works for them:

-

Xplore how operators and innovators are already applying modular, composable thinking in practice.

-

Xperiment through small, de-risked pilots that combine continuous learning with real-world Xperience.

-

Xecute your transformation with confidence by comparing frameworks and technologies before major commitments.

-

Xpand and Xcelerate your capability by collaborating with trusted peers and innovation partners.

-

Xchange learning through the SCL-X INSIGHTS knowledge base and Xcel by turning ideas into action.

the test

Is it right for me?

| Opportunities | Risks |

| Faster cycles, capital-efficient pilots, less technical debt, strategic fit, momentum from early wins and access to diverse innovation partners. | Governance, cyber exposure, internal skills, scalability, orchestration and vendor maturity. |

- Your supply chain has complex interdependencies between functions or business units

- Data gaps, systems or limited capacity are slowing progress

- It’s hard to quantify ROI or build a confident business case for change

- Deploying AI effectively remains out of reach

- Your operating model needs to adapt faster to external pressures

- Innovation needs to deliver more than incremental process efficiency

- Your supply chain is stable, predictable and insulated from disruption

- Data in your organisation is mainly used for reporting, not for driving decisions or innovation

- Your processes are highly standardised and fit well within existing ERP modules or out-of-the-box solutions

- You have little influence over how your supply chain operates or invests (e.g. it is mostly outsourced or innovation is managed entirely by a central IT or transformation function)

- Strengthening competitive advantage isn't a strategic priority

how to get involved

BE PART OF THE SCL-X MOVEMENT

ATTEND

SCL-X LIVE • 29 APRIL 2026 • LONDON

For supply chain leaders and transformation teams

Join peers tackling today’s operational challenges while shaping tomorrow’s composable supply chains.

PARTNER

WITH SCL-X

For innovators, technology providers and consultancies

Collaborate with forward-thinking operators on capital-efficient pilots and real-world case studies.

Share proven approaches, build trust and explore partnership opportunities that create measurable value.

SUPPORT

THE SCL-X COMMUNITY

For thought leaders and practitioners

Help advance the conversation by contributing case studies, frameworks or field experience to SCL-X INSIGHTS.

Show what works in practice and learn from others doing the same.

29 & 30 APRIL 2026 Central London

SCL-X LIVE

Join a curated group of supply chain leaders to explore what’s working - and what isn’t - in modular innovation.

What makes it different:

- Operator-first. The agenda is shaped and led by practitioners. Vendors and investors are in the room, but always in support of operator perspectives.

- No sponsor pitches. Sponsors help make the event possible, but they don’t control the stage. Every session is focused on peer-led discussion and practical insights.

- Working format. Expect labs, workshops and debates that dig into real challenges...not just slide decks.

- Practical playbooks shared by peers

- Benchmarks you can take back to your board

- Connections with other operators facing the same challenges

Who's in?

Supply Chain Leaders

Adam Grimwood

Business Technology Partner

ASSOCIATED BRITISH FOODS

Nicole Kurz

Group Supply Chain Director

LACTALIS UK&I

.jpg?width=500&height=600&name=Brian%20McConville%2c%20BAT%20-%20SCL-X%20profile%20(1).jpg)

Brian McConville

Lead Global Process Expert - SC

BAT

Sam Howell

Supply Chain Director

ITSU

Danny Stubbs

Supply Chain Director

BACARDI

Neil Brown

Supply Chain Director

MARTIN BROWER

Who for?

SCL-X is first and foremost for supply chain leaders, the grassroots of this ecosystem.

It's also for established tech innovators adapting their stacks to modularity; emerging tech innovators partnering with operators and incumbents; investors removing barriers to value creation; and ecosystem partners who enable and connect.

Supply chains lead the conversation; the ecosystem turns needs into action.

- Supply Chain Leaders

- Established Tech Innovators

- Ecosystem Partners

- Solve challenges faster through low-risk trials

- Combine your IP and data with best-fit solutions

- Build resilience without full system overhauls

- Align solutions to priority operator needs

- Extend platforms through partnerships

- Gain insights into enterprise buying decisions

- Engage with operators and innovators

- Find transformation opportunities

- Share expertise shaping the future

"I really enjoyed the day and thought it was well organised and informative. I did go into this thinking it was going to have some hard sell but that was not the case and the vendors were really part of the discussion"

Stuart Pritchard

RTS Textiles

"Very clear, loved the online personal agenda, time to set up my preferences etc. Had three people from very different industries yet common problems, great to connect and share insights."

Mike Shaverin

Mars

"A good day; glad I made the effort and several follow-ups already in progress"

Iain Harris

KP Snacks

"Numbers of people just right and allowed individuals to properly catch up. Atmosphere was relaxed and liked that the sales pitches from those companies sponsoring was relatively informal"

Neil Brown

Martin Brower

"Another super valuable session with an amazing mix of people who are all solution driven"

Matt Spencer-Skeen

Mundipharma

"A great mix of scale of business, industries and experience. I love the format of structured 121s with peers. I came to this with a real lack of understanding of the potential for AI, so this was an eye opener for me"

Dan Bird

Abcam

"Realised that others are also operating with a high degree of uncertainty following not just external macro economics dynamics but structural changes taking place internally. Clarity on the 3 problems we a trying to solve"

Angelo Bernardinello

LSA International

"[Discussions were the] best bit… Great to share and get each other's input and insight"

Adam Grimwood

AB Agri

"Was a great session and got some good information out of the day"

Lee Crowhurst

Cranfield Aerospace

"Sessions were insightful and good to see a range of speakers from different industries and consultancy as well as practitioners. Personal agenda is very helpful and also seeing who else will be joining the sessions is beneficial"

Matt Normington

LEGO

"Very informative and good to hear real life experiences not just theory. I felt my time was being treated as important and not being wasted. Made some good contacts and shared some valuable tips. Great fun at the end"

Alan Clarke

Landmann

"A very worthwhile day. A really great bunch of attendees and good roundtable discussions. I am going to try and push forward some AI initiatives…start small and grow"

Damian Bates

Atlas Copco

SCL-X INSIGHTS

Start here

Oct 3, 2025 12:57:56 PM 6 min read

What Iterative, Agile and Composable Approaches Really Mean in Practice

Oct 1, 2025 3:51:21 PM 4 min read

From Monolith to Modularity: Lessons from Burberry’s Supply Chain IT Journey with Nick Miles

Apr 8, 2025 10:45:00 AM 4 min read

Why the Current Innovation Model is Under Pressure: Part 1 - Systems & Process Architecture

Specialist Investors

Supply Chain & Logistics Leaders

Focused Roundtable Discussions

One-to-One Meetings

SCL INVESTOR

JOIN THE SCL-X MOVEMENT!

Be part of the network reshaping how supply chains innovate and get early access to every new insight, conversation and opportunity.

Each month you’ll receive:

-

Case studies: How peers are testing and scaling modular approaches

-

Playbooks: Frameworks and checklists you can apply immediately

-

Signals: The latest startups, tools and practices shaping supply chain innovation

- Invitations: First notice of upcoming activities, events and collaboration opportunities

PRODUCED BY

BESTPRACTICE.CLUB

Years of SC&L Events

Leaders Participated

Sessions Delivered

Connections Made

FOUNDING PARTNER

.gif?width=120&height=60&name=Animated%20SCL-X%20Logo%20(400%20x%20200%20px).gif)